Materials that become an integral part of the finished product and that can be easily traced to it are called direct materials. Direct materials usually consists of a https://justiceandequalityforall.com/examples-of-liabilities-2/ significant portion of total manufacturing cost. Remember, the choice of allocation method depends on the organization’s specific needs, available data, and management’s preferences.

Customer ServiceCustomer Service

By considering different perspectives, utilizing cost allocation methods, and conducting in-depth analysis, organizations can make informed decisions to optimize their operations and improve profitability. On the other hand, a product with a low gross profit may actually be very profitable, if it uses only a minimal amount of administrative and selling expense. These costs are not directly tied to the production of goods or services, but rather to the overall operation of the company.

Inventories in manufacturing process

Entities may manufacture several types of products and the sum total of all the costs involved in producing those products is termed as manufacturing cost. The sum of direct labor cost and manufacturing overhead cost is known as conversion cost. The sum of direct materials cost and direct labor cost is known as prime cost.

- Therefore, parts have a variable nature; the amount of raw materials bought and used changes in direct proportion to the amount of valves created.

- The more valves are produced, the more parts Friends Company has to acquire.

- Manufacturing overhead includes the indirect materials and indirect labor mentioned previously.

- Recall from other tutorials that variable costs change in proportion to production.

Direct Labor

- Sometimes it is difficult to discern between manufacturing and non-manufacturing costs.

- A current asset whose ending balance should report the cost of a merchandiser’s products awaiting to be sold.

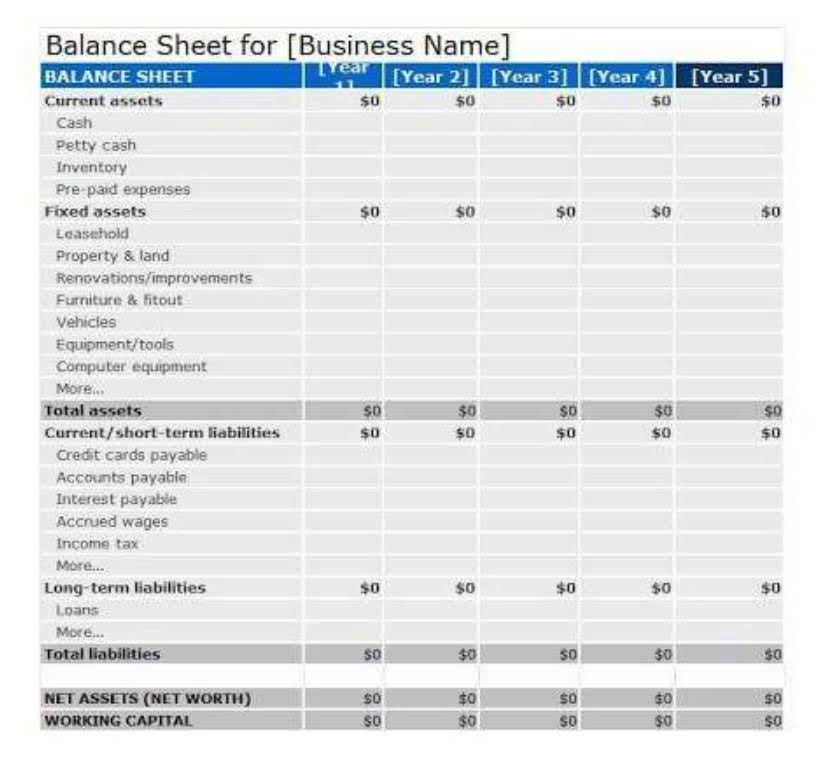

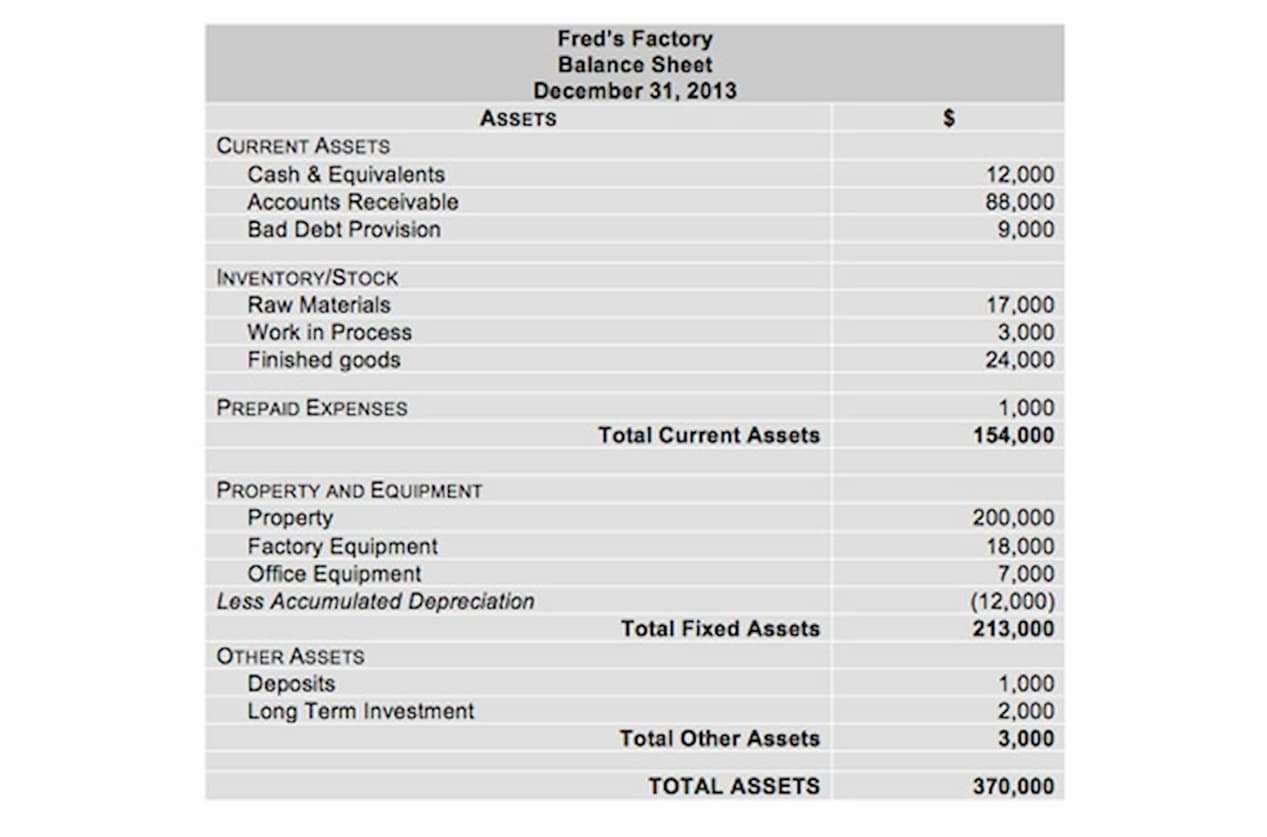

- The balance sheet reports the assets, liabilities, and owner’s (stockholders’) equity at a specific point in time, such as December 31.

- This method focuses on the time required to perform various service activities.

- Examples of administrative costs include salaries of executives, accounting costs, and general administration costs etc.

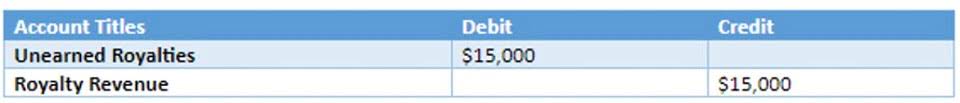

Product costs are assigned to an inventory account on the balance sheet, initially. When finished goods are sold, the cost of goods sold is transferred to the income statement (expensed) and matched with the sales revenue. As product costs are assigned to inventory accounts initially, sometimes they are called inventoriable costs. MasterCraft records these manufacturing costs as inventory on the balance sheet until the boats are sold, at which time the costs are transferred to cost of goods sold on the income statement. Examples of selling costs for PepsiCo include television advertising (probably the biggest piece of the $22,800,000,000), promotional coupons, costs of shipping products to customers, and salaries of marketing and advertising personnel.

The sum of direct materials cost, direct labor cost and manufacturing overhead cost is known as manufacturing cost. Understanding non-manufacturing costs is essential for effective financial management. By analyzing these costs, organizations can make informed decisions, allocate resources efficiently, and improve overall performance. Remember that non-manufacturing costs are not just expenses—they represent investments in the organization’s growth and sustainability. Examples of general and administrative costs include salaries and bonuses of top executives and nonmanufacturing costs the costs of administrative departments, including personnel, accounting, legal, and information technology.

Nonmanufacturing Overhead

The inventory of a manufacturer should report the cost of its raw materials, work-in-process, and finished goods. The cost of inventory should include all costs necessary to acquire the items and to get them ready for sale. Nonmanufacturing https://www.bookstime.com/articles/ap-automation-for-manufacturing-companies overhead costs are the company’s selling, general and administrative (SG&A) expenses plus the company’s interest expense. While depreciation on manufacturing equipment is considered a manufacturing cost, depreciation on the warehouse in which products are held after they are made is considered a period cost. While carrying raw materials and partially completed products is a manufacturing cost, delivering finished products from the warehouse to clients is a period expense.